- Careers

- Media & Events

- Downloads

-

- Europe

- Belgium

- Germany

- United Kingdom

- France

- Austria

- Switzerland

- Czech Republic

- North America

- Canada

- USA

- Middle East & Africa

- United Arab Emirates

- Saudi Arabia

Everything began in Heilbronn, more than 170 years ago. With the milestone set in 1913 – the first mobile and fast-assembly tower crane developed by chief engineer Göbel - WOLFFKRAN quickly becomes the industry’s innovation leader and global crane specialist.

As the leader of the pack, WOLFFKRAN since sets standards in technology and service, integrates state of the art drive technology in its cranes, and continuously develops new models – for more efficiency and safety during transportation, assembly and operation on the construction site.

Go East: WOLFFKRAN establishes the new subsidiary WOLFFKRAN for Equipment in Saudi Arabia and enters into a joint venture with the Zamil Group to set up a new production facility in the Kingdom as well as its own rental fleet for the entire MENA region.

Digitalization has become an integral part of modern construction sites. WOLFFKRAN launches the High-Speed Positioning System (HiSPS), a digital, BIM-compatible assistance system that revolutionizes load movement by stopping the crane hook from swinging and enabling crane operators to position the load precisely, safely, and efficiently.

The red WOLFFs are heading north. WOLFFKRAN Holding AG and Norwegian Mikkelsen AS have established the joint venture WOLFFKRAN Norge AS.

The WOLFF pack is growing. WOLFFKRAN acquired the Czech crane rental company KONSTRUKTIVA LOKUS a.s. The Prague-based company is an established player in the Czech market since decades and expands the territory of the red WOLFFs in Central Europe.

WOLFFKRAN developed the TV 60 tower section with a dimension of 6 x 6 meters to meet the requirements of the dam project Spitallamm in Switzerland. The first TV 60 tower sections were assembled on the high-alpine construction site in late summer 2020.

WOLFFKRAN starts production in Russia and has taken another important step in its globalization strategy. The plant is located about 140 kilometers southeast of Moscow in Lukhovitsy.

The leader of the pack is expanding its territory and investing in a new European market. Since the end of 2017, the globally active crane manufacturer and rental company WOLFFKRAN is represented with a sales and service branch in Paris, France.

WOLFFKRAN acquires the business of the leading crane rental company in the UK, HTC, and grows by 320 new employees.

Go west: WOLFFKRAN is back in the US market with its own subsidiary outside of Manhattan and WOLFF luffers 700 B on high-rise projects in San Francisco and New York (3 WTC).

100 Years Tower Cranes: at bauma 2013 WOLFFKRAN celebrates tradition and innovation under the motto of “WOLFF Tower Cranes 1913 – 2013”.

As global player WOLFFKRAN is active on some of the most prestigious construction sites around the world – as for example, with approx. 60 cranes on the extension of the Holy Mosque in Mecca, Saudi Arabia.

WOLFFKRAN opens its new production facility in Germany: Luckau in Brandenburg – responding to increasing worldwide demand.

A year later the BIG WOLFF 1250 B luffer celebrates its premiere: a giant, in particular for power plant construction. It continues the successful new line of luffers with patented design of the counterjib-tower top-unit – introduced a year earlier with the 355 B.

Dr. Peter Schiefer acquires WOLFFKRAN and as new CEO places the focus on two things: innovation and internationality

WOLFFKRAN is globally active – with new subsidiaries and partners in Central Europe, Middle East, North America, Australia and Southeast Asia.

WOLFFKRAN Schweiz is ready to go: the new subsidiary in Switzerland is the result of the acquisition of the crane division of Robert Aebi AG in 1999. WOLFFKRAN thus strengthens its position in the Swiss market.

The XXL crane series is introduced: with a jib radius of more than 90 m and a lifting capacity of up to 50 tons, the XXL WOLFF cranes set new standards.

From now on, every new WOLFFKRAN is equipped with the efficient FU drive.

WOLFF cranes are equally present on construction projects in the booming Tiger States, as on high-rise building dominating the Frankfurt Skyline (Commerzbank).

The world’s first hydrogen powered car is presented to the public.

The leader of the pack proves its strength on difficult terrain too – as for example on the spectacular construction site on the Säntis summit (2500 m.a.s.l.) in Switzerland.

One year later, the member states of the EC join to form the European Union, based on the Maastricht Treaty.

The innovative B-series of the WOLFF luffing crane is well established.

The fall of the Berlin Wall in November 1989 sets off a construction boom in Germany. Red WOLFFs characterize the city scape of many cities in eastern Germany, on constructions sites of the new main station in Berlin and Dresden for example.

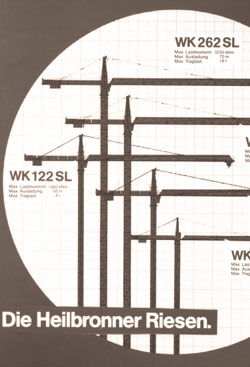

With the new SL series, WOLFFKRAN rounds off its product portfolio: it now has a crane to meet every demand.

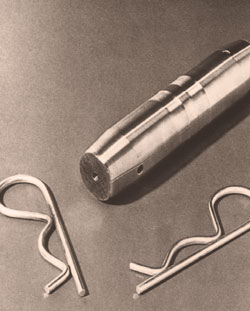

With the introduction of the groundbreaking pin connection, WOLFFKRAN lays the foundation stone for modular technology in the construction of tower cranes. A technology which continues to lead the way to dateWith the introduction of the groundbreaking pin connection, WOLFFKRAN lays the foundation stone for modular technology in the construction of tower cranes. A technology which continues to lead the way to date.

The construction of the world’s largest dam, the Aswan Dam, is well underway. WOLFF cranes are in operation in the rescue of the rock temple at Abu Simbel in 1964.

WOLFF celebrates its 100-year anniversary. A year earlier, the Maschinenfabrik Augsburg-Nürnberg AG - M.A.N. invests in 51% of the shares of Jul. Wolff & Co. GmbH.

“The Miracle of Bern”: Germany wins the World Football

Championship.

Wolff and Kran (crane) become WOLFFKRAN, thereby combining company and product in one name - a name which comes to present the ultimate in quality and cranesational technology.

VW Beetle production begins in Wolfsburg – one of the world’s most built cars.

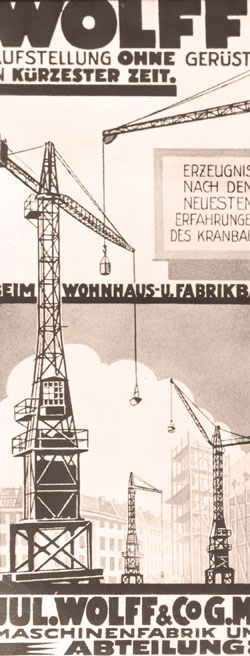

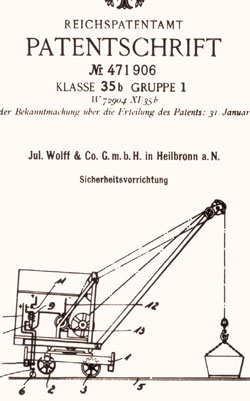

Jul. Wolff & Co., acting as a GmbH (Ltd) since 1921, consistently consolidates its technological leadership in the tower crane market. In 1931 it enters the Swiss market – the beginning of a close and successful partnership.

In 1927 Charles A. Lindbergh is the first to fly solo across the Atlantic from New York to Paris.

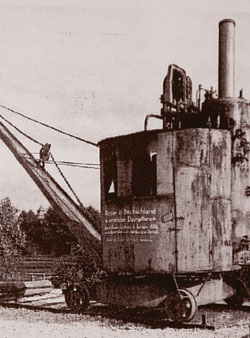

WOLFF presents the first fast-assembly, mobile, top-slewing tower crane in the world at the Leipzig Exhibition. A milestone - and the beginning of the success story of the "Heilbronn Giants".

Henry Ford reduces the assembly time for a "Tin Lizzy" car from 12.5 to 1.5 hours through assembly-line production.

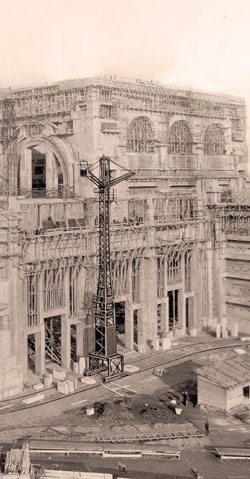

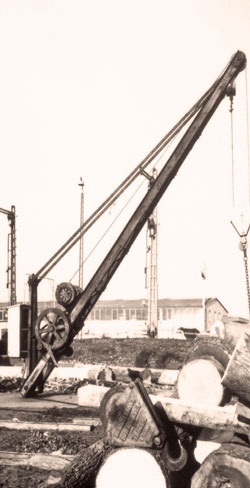

Crane construction in Heilbronn becomes increasingly important, though at first with small hoisting cranes and not the red “giants” of later years. In 1898 the first slewing crane leaves the WOLFF factory in Heilbronn.

In 1896, the first Olympic Games of modern times take place in Athens.

The son continues what his father Julius had begun: Richard Wolff continues to specialize in hoisting and conveying engineering. As a result, WOLFF designs and constructs steampowered, chain hoist drives for the Neckar shipping.

In 1886, the success of Coca Cola, which originally sold as medicine against fatigue and headaches, is established.

Alongside cast iron goods such as steam engines, rollers, ship bollards and turbines, Julius Wolff, youngest son of the company founder, also develops new ideas for hoisting: his aim is to improve and bring to the market innovative lifting equipment and elevators.

1871 The Prussian Chancellor Bismarck founds the German Reich.

Friedrich August Wolff, a pewterer by profession, founds an iron foundry in Heilbronn. Cast iron production starts on August 19, 1854. This date marks the beginning of the continuous development of a company bursting with ideas and creativity.